Stamped Brasses

Stamped brasses appeared on the scene around 1880 and production of these peaked shortly before WW1. Since the 1920s a few designs have continued to be made from thinner gauge brass sheet.

Due to serious concern about the combined weight of cast harness decorations carried by working horses (first raised by the early animal welfare movements in the 19th century) it is thought that the first stamped brasses were made as a lighter (and cheaper) alternative to cast brasses being later exported throughout the British Empire. Unlike their cast cousins stamped brasses were not made in moulds but pressed out of rolled sheet brass approximately 1/16 inch in thickness, later thinner gauge sheet was used after WW1.

The machine used for stamping was called a flypress or flywheel press. It was a mechanically driven ram, the power to the ram being provided by a heavy, constantly rotating flywheel which drove the ram using a Pitman arm. In the 19th century the flywheels were powered by leather drive belts attached to line shafting which in turn ran to a steam engine. These early pressing machines stamped out blanks complete with a hanger. The blanks would then be stored to await further processing by skilled operatives using a punch press to form both simple and more intricate patterns. This involved additional die tools that would emboss or remove sections of the blank thus forming the patterns we know today. The process is covered in some detail in the NHBS video/DVD entitled ‘Horse Brasses, Origin, History & Collecting’.

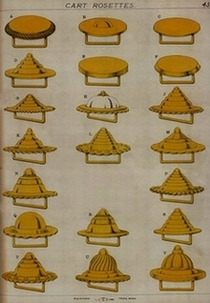

Other examples were simply pressed and cut in a single operation requiring no additional work other than polishing prior to sale. These were fashioned using specially-made positive and negative dies. Brass sheet was fed between the falling die tools cutting and pressing out the shape required in one blow ready for sale.

Over time these dies were further developed so that stepped cones (also called ‘bee hives’), dome, raised ring and floral shapes were included in the production process. The blanks could now be embossed prior to the other cutting dies being employed to remove shaped pieces (called ‘cut outs’) around the border.

No one is sure how the blanks were positioned so that the cutting and perforating of the ‘surround’ could be undertaken. Evidence suggests the operative did most of it by eye, as a number of ‘Friday afternoon’ brasses exist where the cut outs are very unevenly placed.

Towards the end of the 19th century a new type of stamped hanging brass appeared, fitted with an applied ceramic pot centre (often made in the Staffordshire potteries) held in place by a brass split-pin with a decorated head. A variety of plain colours were available but many had patriotic red-white-and-blue concentric rings. Matching pot rosettes were also made.

Sometime around the 1950’s a poorer quality pot type appeared ( both cast and pressed housings were used )This line introduced additional colours to the range of ceramic centred brasses; yellow, olive green, and plum now appeared.

The development of stamped brasses with a Royal theme is also interesting; the first types concerned Queen Victoria, a cast bust of this monarch was attached to a pressed blank having an embossed diamond surround. Another was created in much the same manner using one with a diamond surround. At the time of her death in 1901 a brass commemorating her reign, included lettering for the first time.

Victoria types

Then the following Kings, Edward VII and George V were also given this consideration.

Innovations continued, and specially made brasses now included sepia or coloured photographs of the reigning Monarch; these were covered by celluloid, and inserted into a small-embossed central void.